this post was submitted on 01 Apr 2024

409 points (94.7% liked)

Technology

77954 readers

4035 users here now

This is a most excellent place for technology news and articles.

Our Rules

- Follow the lemmy.world rules.

- Only tech related news or articles.

- Be excellent to each other!

- Mod approved content bots can post up to 10 articles per day.

- Threads asking for personal tech support may be deleted.

- Politics threads may be removed.

- No memes allowed as posts, OK to post as comments.

- Only approved bots from the list below, this includes using AI responses and summaries. To ask if your bot can be added please contact a mod.

- Check for duplicates before posting, duplicates may be removed

- Accounts 7 days and younger will have their posts automatically removed.

Approved Bots

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

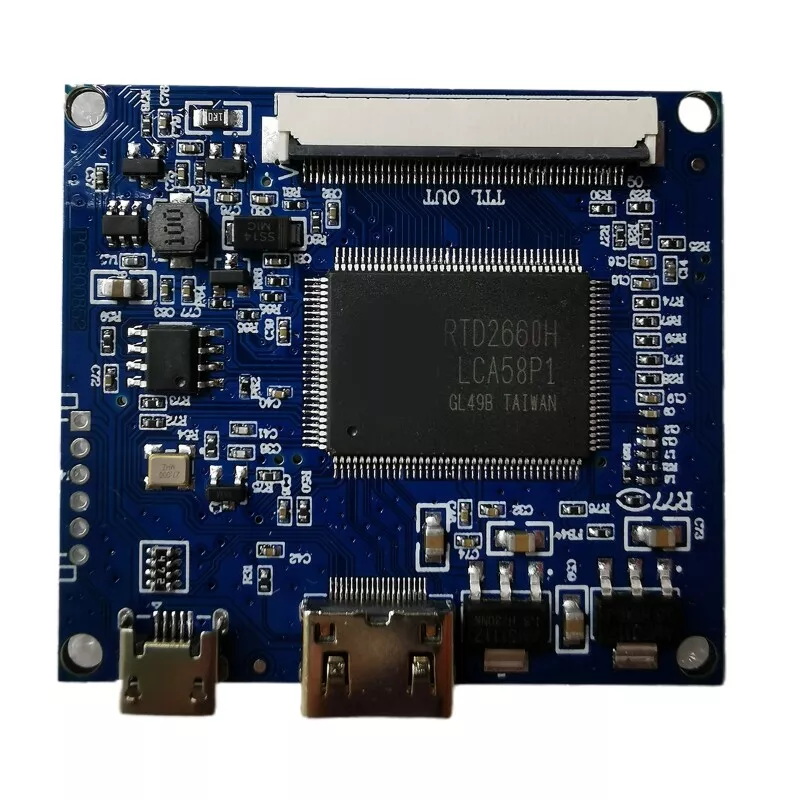

I have rematched controllers to displays in the past. It's neither simple nor easy. You'll need to dig through spec sheets to ensure you're sending the correct signals over the correct pinouts, at the correct frequencies and voltages. Be prepared to read some IO documentation for the sending and receiving chipsts, then verify pinouts with certainty. They are not always standard.

Here are 2 identical LCDs, with 2 very similar, nearly identical looking controllers. Note that one needed to be re-wired. It is not fun butt-connecting 2 dozen 28ga wires.

The in-rush of endorphins when the modded LCD thing actually worked probably knocked you out?

A bit of a side story: I disassemble probably 1–5 panels in a week. (For recycling, it takes about 20-45min per panel.) The flat cables alone are so flimsy, I would say just assembling a display again from known, matched and functional parts would take days. I would triple or quadruple that to assemble a display from random parts. Considering this, that modded panel is quite amazing to me.

In standalone panels, the PSU has a chance of killing you: the main capacitors can hold multiple joules worth of nope, charged to about 400v. So, if the main caps are not allowed to discharge (if they discharge at all that is), there is a possibility of death when disassembling a panel with an integrated PSU. Waiting "5min" is bad; a PSU needs to be unplugged for a day or two at least before the charge drains out.

Why did you do it?

I was a poor college student and had access to engineering samples from a local manufacturer. Discarded parts gave me twin 15" LCDs for free in the mid 00's. Also, to see if I could. It was a fun challenge. These are different revs of a controller that were outfitted in several slot machine prototypes. They gave me many years of service. I probably still have inkjet prints of the pinout and signal diagrams, somewhere.

Seems like a fun project to me too. It also seems like things have changed since the turn of the century, with regards to interoperability.

Oh, things are way better now than they were back then. I'd still confirm via documentation that the interfaces are compatible :)

I retired from embedded systems design and design-for-manufacture a decade ago. Reading datasheets was most of the job. This doesn't look too daunting. It's a single interface between two readymade components. I've identified where some issues might come up, and there are probably some that I don't know about yet. Still this seems less like building a circuit around existing ASICs and more like hooking up stereo equipment to me.