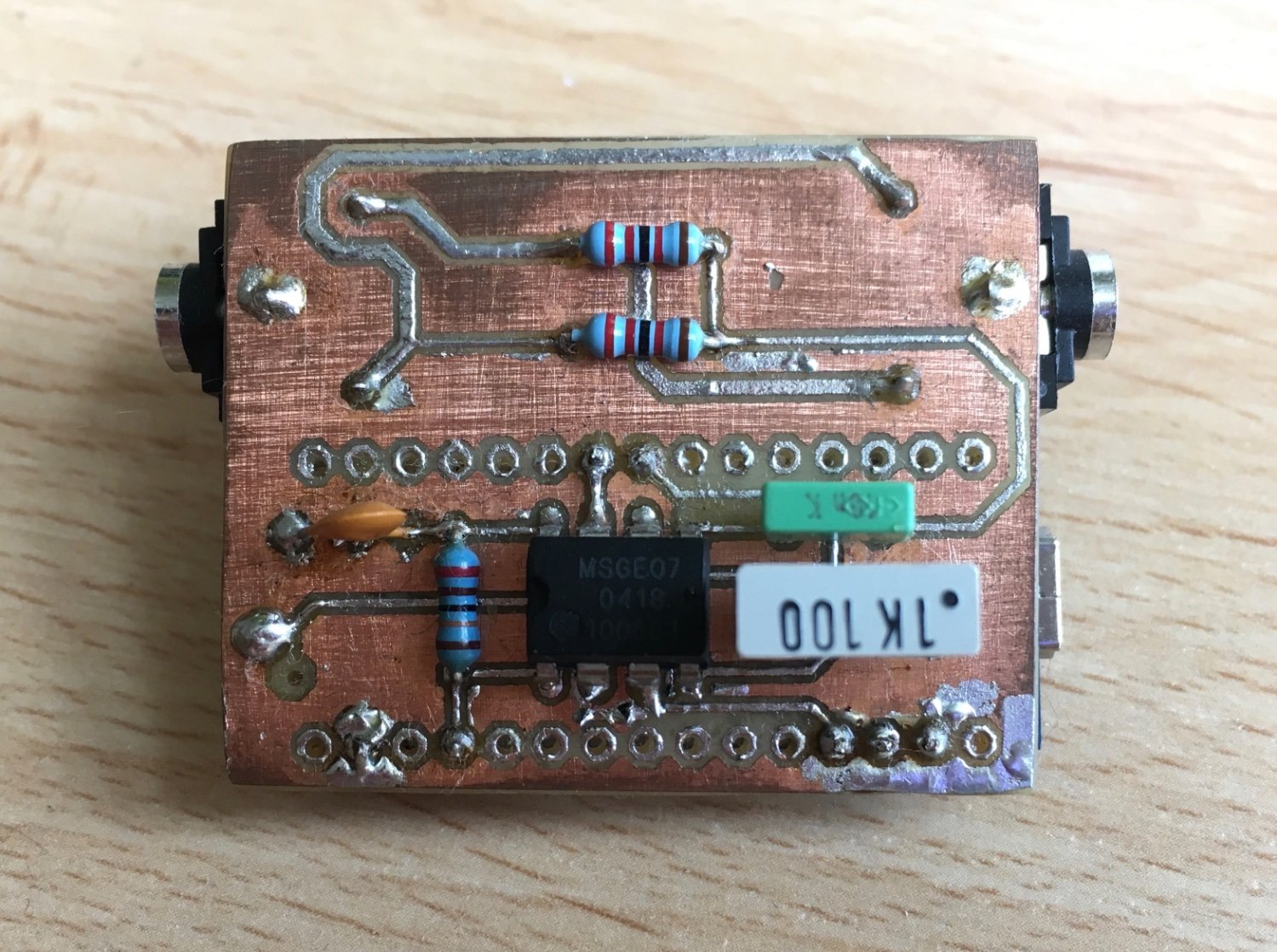

Haha, the board won‘t win any prices for sure. But for a first try I‘m still very happy.

bistdunarrisch

joined 10 months ago

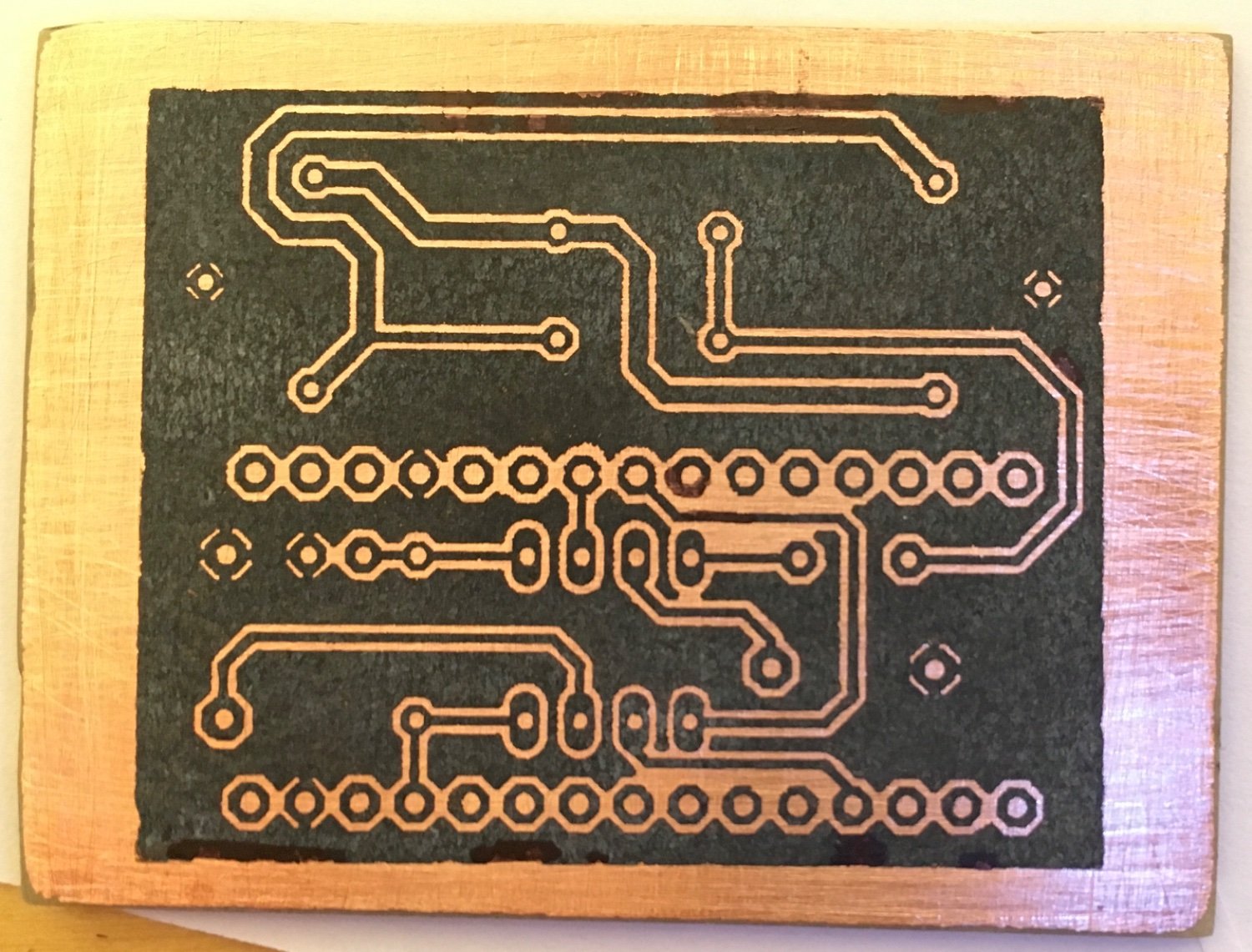

I just printed the design on a glossy paper and used an iron to transfer the toner from the paper onto the pcb (last image). The toner protects the underlying copper in the etching process, so only the free copper gets etched away. I used Na2S2O8 for etching.

Yes UV is so much nicer, I also use this method now when I‘m not ordering online.

Interesting, how much power does the laser have to need to be able to burn the paint?