That, or even street drugs are so expensive now no one can afford them. Damn inflation...

dual_sport_dork

I would have left a thumbtack on every chair, and a bucket of whitewash balanced over every door.

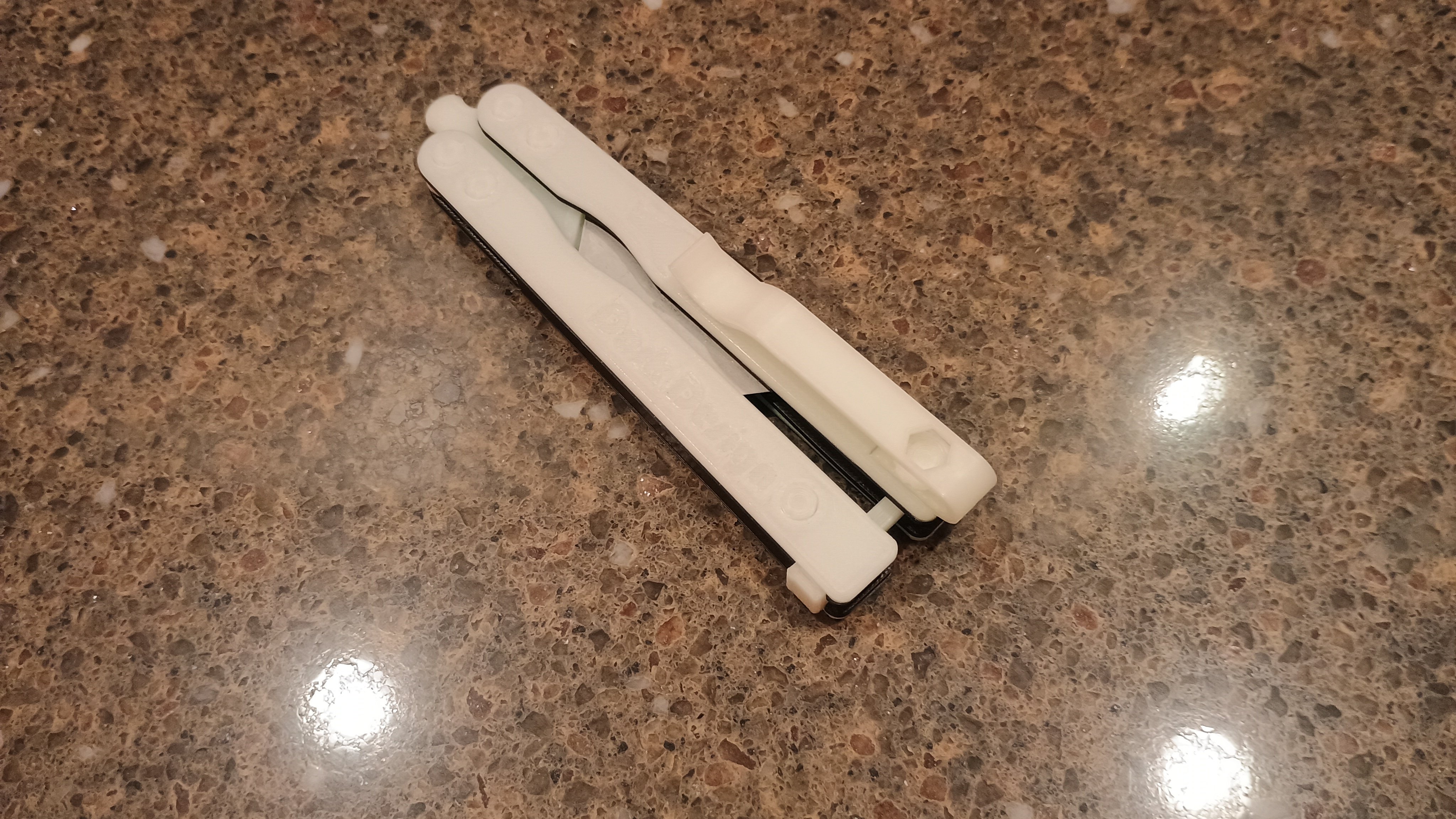

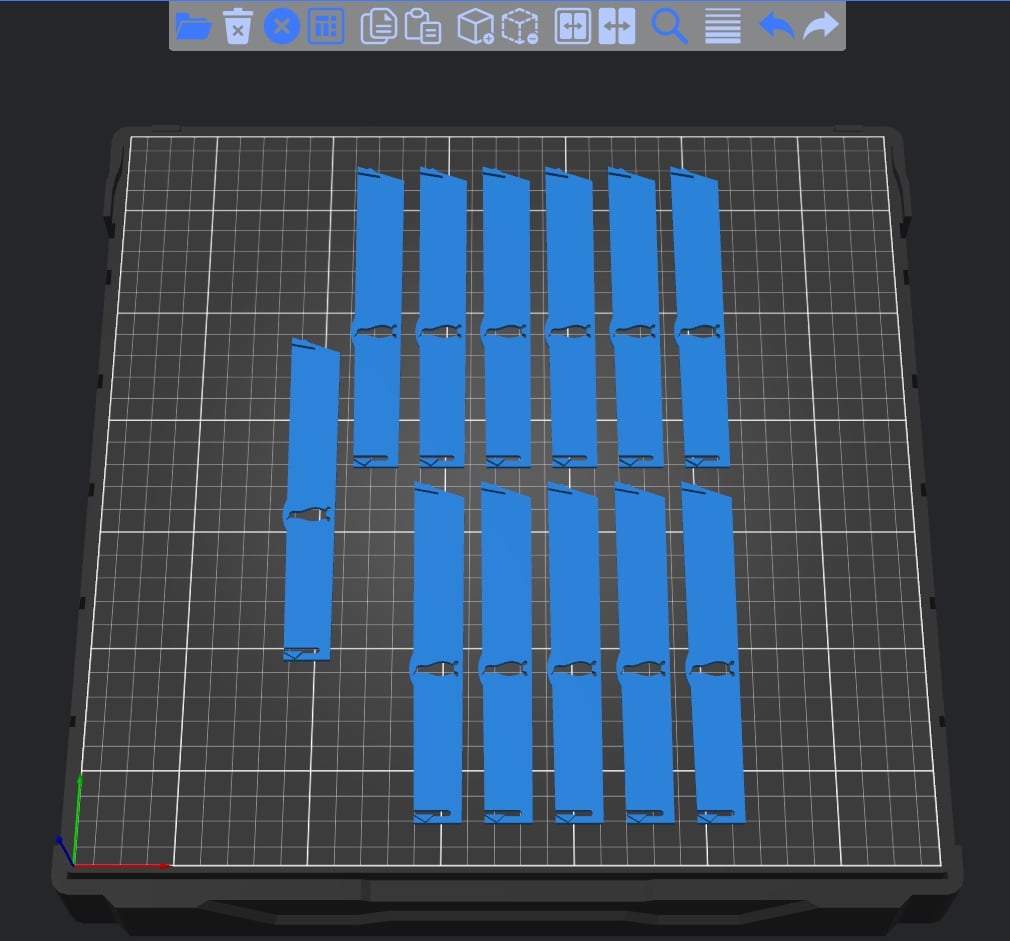

Dem overhangs, tho. Did you print this upside down, with the open end on the print bed? It looks quite good.

I think PETG is probably a good choice for this application. PLA, especially if it's thin walled as I suspect it is here, will disintegrate pretty quickly with continued exposure to temperature variations, moisture, and sunlight.

ABS is infamously pretty vulnerable to UV, also. You could protect it (or any of the others, really) with a coat of paint.

How we have lost perspective. When I was that age I was forced to walk to school, a distance of about 1.5 miles.

Forced, mind you, because if you were considered "too close" to the school you were not eligible to ride the bus. Other than the land directly adjoining the school grounds, the roads I had to use also did not have sidewalks. The number of children killed, maimed, or injured by this during the years I attended that school were, to my knowledge... zero.

As for why: I have no idea! Maybe just for user familiarity reasons, since a lot of people grew up with that kind of analog feedback that the antenna wasn’t getting a signal.

This is exactly why. Preventing screen burn-in may be a tiny peripheral reason also, but providing a familiar experience to chronically myopic and cranky users (i.e. boomers) is probably the bigger one.

The trope of video/audio breaking down into static is an easy shorthand that is unlikely to be forgotten, probably even well after all the devices capable of doing so have long since been buried in the landfill.

It's especially hilarious in media depicting the far-flung future, where apparently all technologically advanced space men and their communications devices -- not to mention high powered central supercomputers and so on and so forth -- somehow still work over NTSC television signals. Even by the early 1980's it should have been entirely predictable that in "the future" anything like that would be digital, considering we already had widespread digital audio media (CD's), and digital video was already making inroads into the computing industry.

Tube TV's remained in common service well into the 2010's. The changeover from analog to fully digital TV transmission did not happen until 2009, with many delays in between, and the government ultimately had to give away digital-to-analog tuner boxes because so many people still refused to let go of their old CRT's.

Millions of analog TV's are still languishing in basements and attics in perfect working order to this very day, still able to show you the cosmic background, if only anyone would dust them off or plug them in. Or in many retro gaming nerds' setups. I have one, and it'll show me static any time I ask. (I used it to make this gif, for instance.)

In fact, with no one transmitting analog television anymore (probably with some very low scale hobbyist exceptions), the cosmic background radiation is all they can show you now if you're not inputting video from some other device. Or unless you have one of those dopey models that detects a no-signal situation and shows a blue screen instead. Those are lame.

From a chemical composition standpoint I couldn't tell you, but my off-the-cuff testing indicates that the glow remains visible for quite a few hours -- All night, in fact, though obviously tailing off in brightness considerably as time goes on.

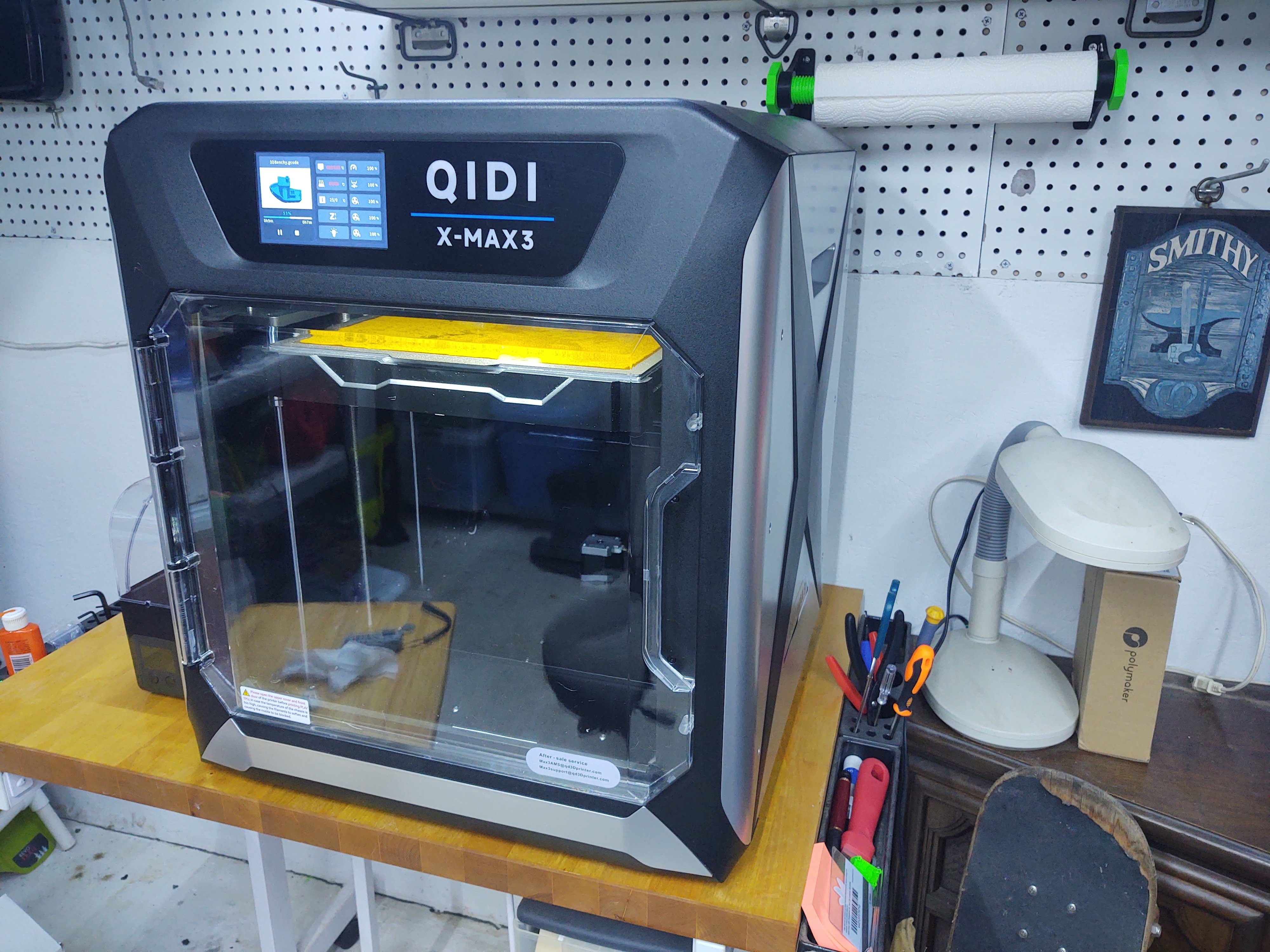

I have a diamond nozzle installed already.

PETG's issue in this particular application is layer strength, wherein it's difficult to top PLA except with some semi-exotic and rather hard to print materials like polycarbonate. Both the screws and the blade carrier in my design rely on layer adhesion not failing for durability. Otherwise honestly the parts are all pretty low stress other than I guess potentially the pocket clip.

For a short time in total darkness it actually is pretty bright. Obviously my phone's camera automatically wound the exposure up quite I bit when I took that picture in the dark, though. That was without any special charge-up, just an hour or so of exposure to the largely LED based lighting in my office with it lying face up on my desk.

This is the Overture brand glow PLA.

I whacked it with my little Lumintop single AA flashlight last night and left it sitting on my bedstand, and found that it was still quite visibly (albeit dimly) glowing by dawn the next morning.

Smooth brain. No ridges or lumps, nor valleys or bumps; all facts and just logic slide right off.

Ask the Filipinos, who are the ones who both invented and named it. "Butterfly knife" is a western neologism for it.