this post was submitted on 22 Dec 2023

47 points (100.0% liked)

Technology

37728 readers

661 users here now

A nice place to discuss rumors, happenings, innovations, and challenges in the technology sphere. We also welcome discussions on the intersections of technology and society. If it’s technological news or discussion of technology, it probably belongs here.

Remember the overriding ethos on Beehaw: Be(e) Nice. Each user you encounter here is a person, and should be treated with kindness (even if they’re wrong, or use a Linux distro you don’t like). Personal attacks will not be tolerated.

Subcommunities on Beehaw:

This community's icon was made by Aaron Schneider, under the CC-BY-NC-SA 4.0 license.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

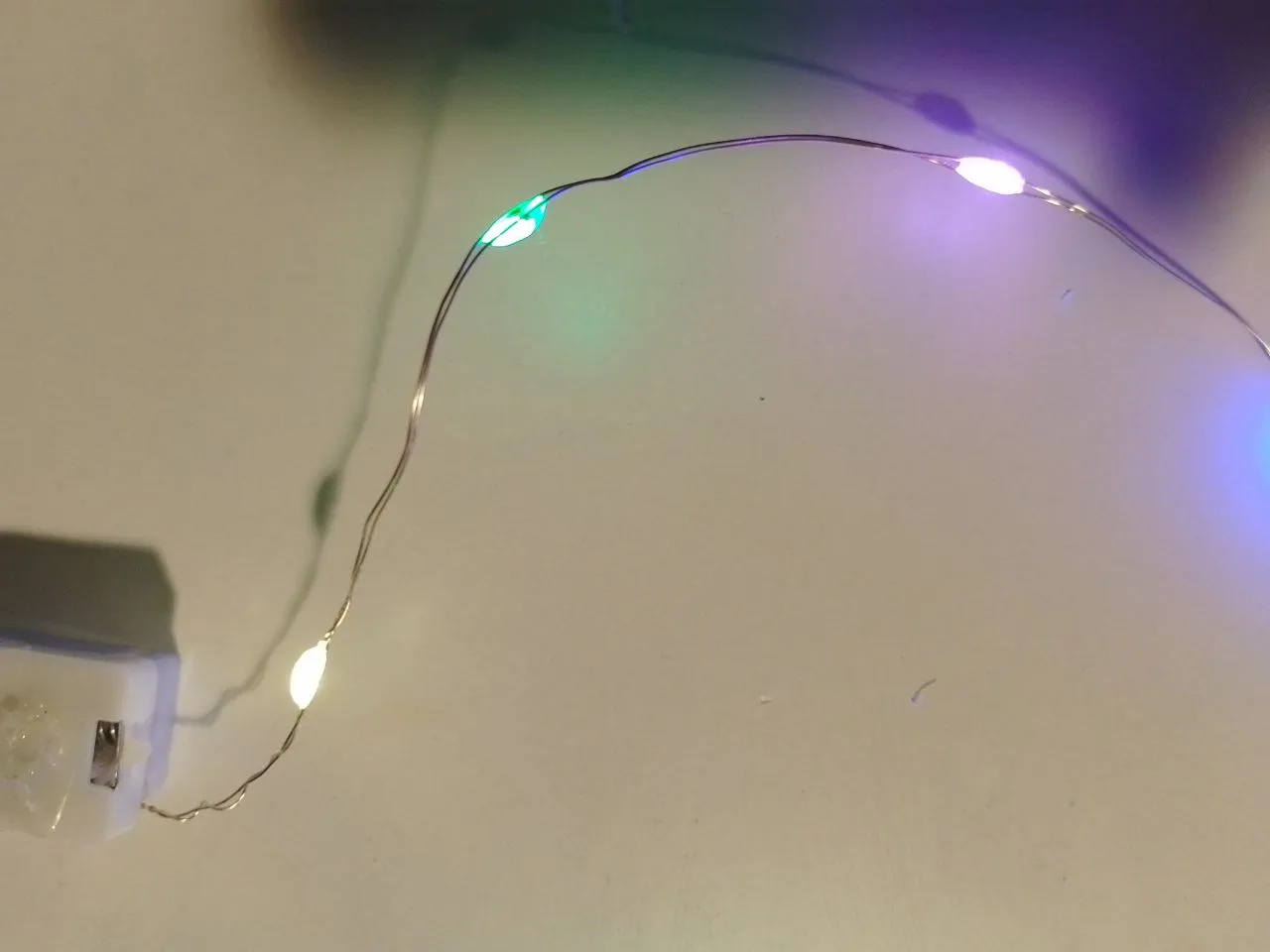

There is a nonconductive coating on the wire that also prevents it from oxidizing. The wires can touch, but if the coating isn't scratched it won't short.

Some fine grit sandpaper will reveal the metal so you can solder connections.

will also see it sold as “magnet wire” (for winding your own electromagnets) and the heat from your soldering iron is usually enough to melt through the enamel varnish

That's generally not recommended as a way of stripping them though, since the coating is often made of polyurethanes, which release alkyl isocyanates (highly toxic) when heated strongly. While a small amount in a well-ventilated area might not be enough to give you any problems, if you get too much it is very bad. The organic material will also impact the ability to solder. Better to scrape it off first.