3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

For strength there are some decent GID PETG options. Glow for all these is pretty good with regards to intensity but poor for duration. Be ready to replace your brass nozzle a little sooner than you thought. Using a oxbidian nozzle and it seems to take the beating well.

I have a diamond nozzle installed already.

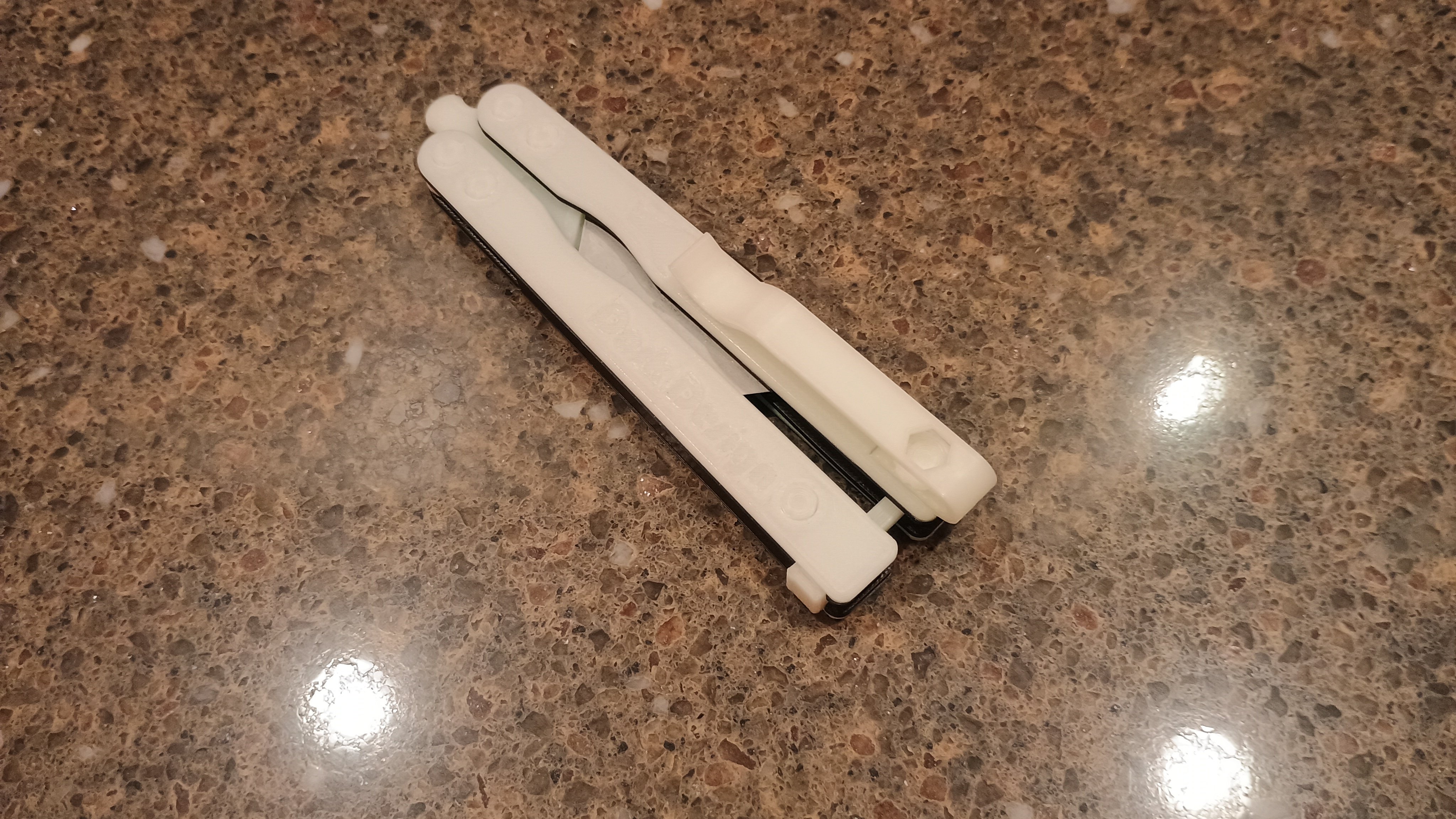

PETG's issue in this particular application is layer strength, wherein it's difficult to top PLA except with some semi-exotic and rather hard to print materials like polycarbonate. Both the screws and the blade carrier in my design rely on layer adhesion not failing for durability. Otherwise honestly the parts are all pretty low stress other than I guess potentially the pocket clip.