Thanks .. I'll let my self know that 4 years ago.

_thebrain_

Green tea can be high in oxalates and most likely was responsible for my first kidney stone.

But when think the comic is pointing out hypocrisy as opposed to the heath benefits of one product vs another

Last I hear OnePlus was on the verge of collapse. Not because of this, but because of the mismanagement since carl left. It will probably be absorbed into oppo soon enough https://www.androidheadlines.com/exclusive-oneplus-collapse.

Fusion works flawlessly for me in winapps (and I'm sure winboat), but it is s-l-o-w. I probably need to figure out GPU passthrough and it might be bearable... But I haven't had much time to dedicate figuring it out.

I would say hans reiser enters the room... But he didn't...

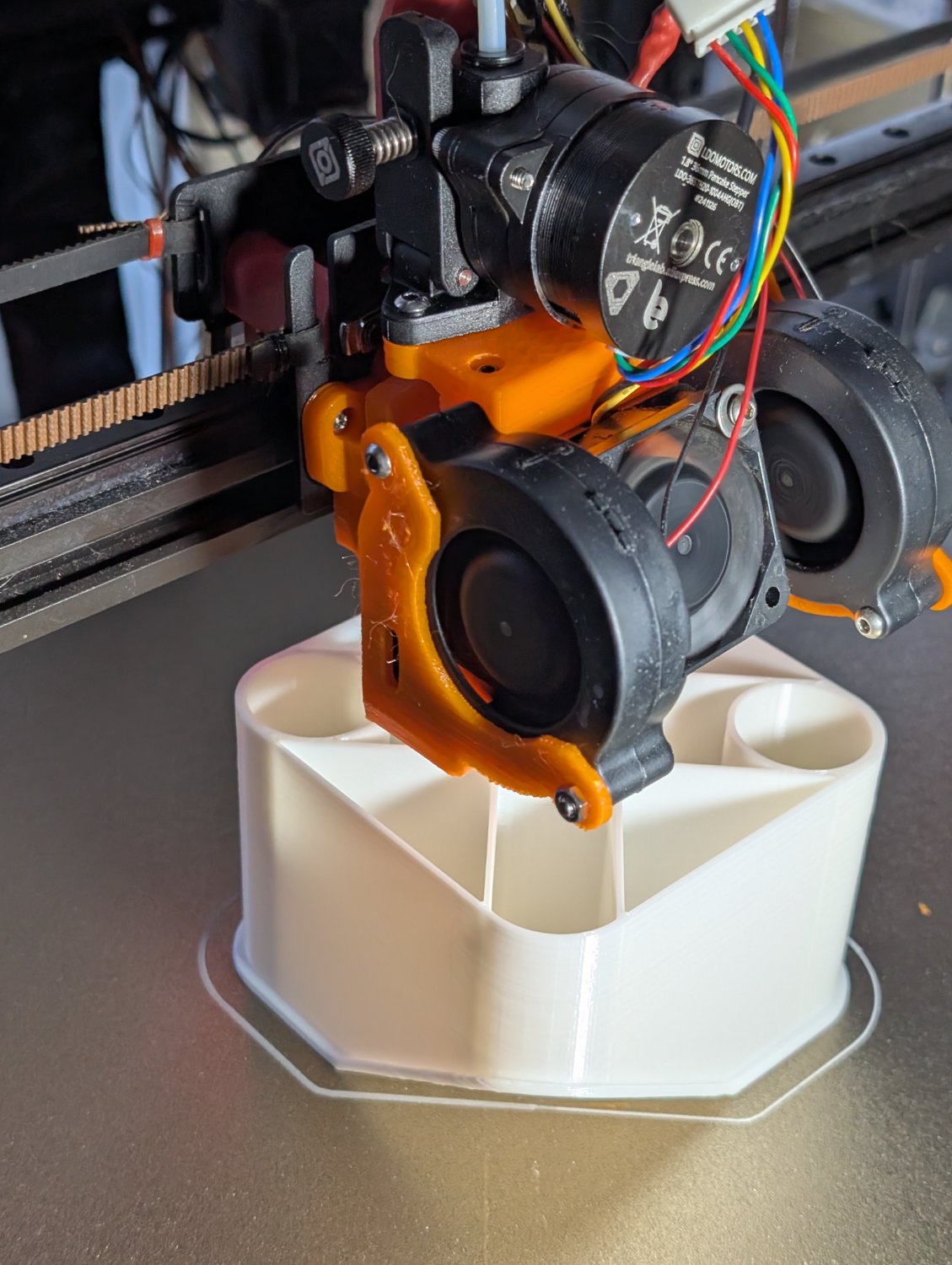

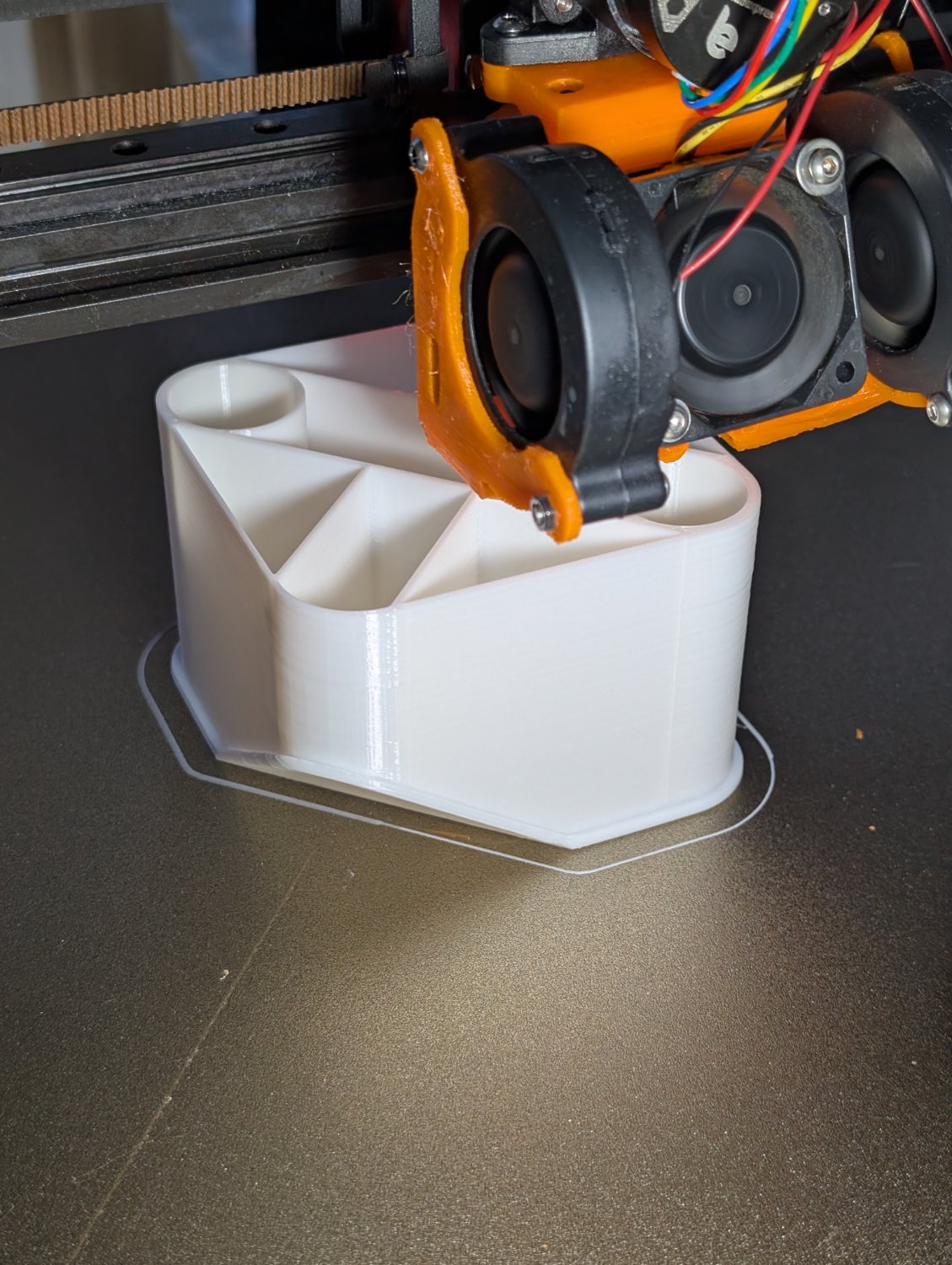

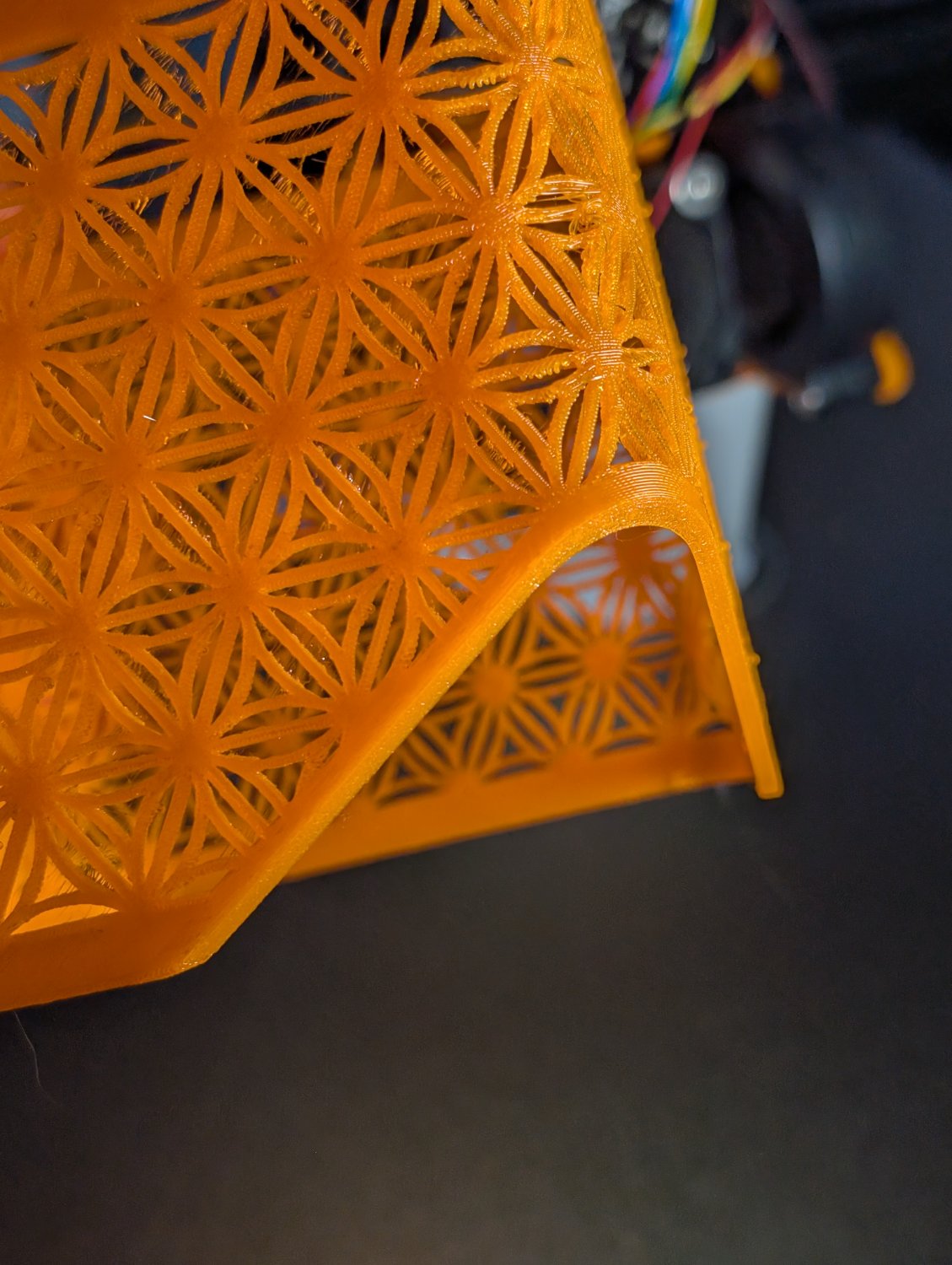

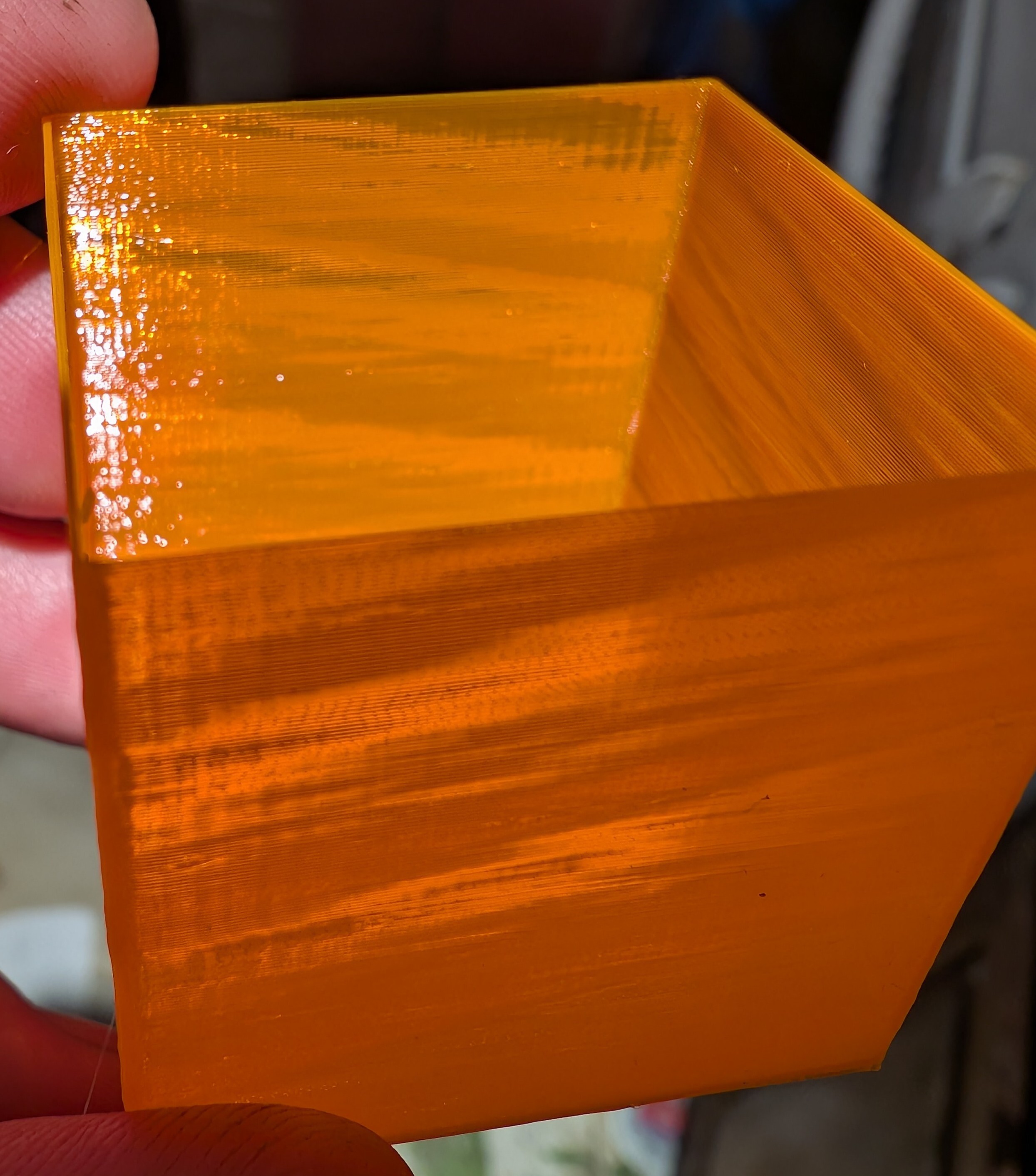

I had similar issues tho on a custom designed printer. The issue ultimately was the adhesive for the silicone heater for the bed was failing ans slowly delaminating from the bed. When I felt the heater it was plenty warm... But when I felt the center of the bed where it prints it was a lot cooler. I had to replace the whole heat pad. I don't know what yours uses to heat the bed but my guess would be that it is also on the way out.

I, for one, welcome our future Canadian overlords, with open arms.

He probably is already pardoned under the blanket one trump signed on his first few days in office

I always thought be was Varicose vein/venous insufficiency Linux... At least that is what it is for me

Tbf the school probably doesn't care if you die either, the bus companies just fear the lawsuits.

I think "technical" is a bit of a stretch... But who doesn't like a good cat meme?

I relate so much except mine shattered and I required a ureteroscopy to go pull out the 3 fragments, after 48 hours of intense pain.

You can look up ureteroscopy as a procedure if you like, but I can assure you it is just as much fun to have done as it is to spell